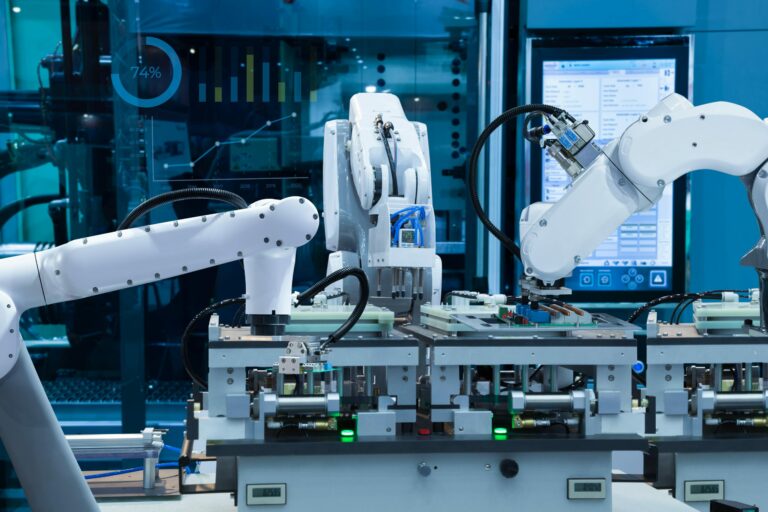

With the shift from traditional human labor to advanced robotic automation, the manufacturing landscape has undergone a remarkable makeover. As businesses are under more and more pressure to increase efficiency and productivity, assembly robots have become crucial in modern workplaces. This article discusses how these new machines are changing manufacturing, the technologies behind it, and potential workforce effects.

Defining Assembly Robots: Types and Capabilities

Some assembly robots are made to do certain things, and each type is designed to do those things. These are the most popular types:

Collaborative Robots (Cobots): Designed to work alongside human workers, they increase productivity without taking away the human touch. Cobots are easy to use and can be programmed for a variety of tasks, making them ideal for smaller manufacturers.

Industry robots are typically larger and more robust, performing fast, repetitive tasks consistently. They work best in places that need to be very precise, like in the electronics and car manufacturing industries.

Autonomous Mobile Robots (AMRs): These robots move materials and components from one workplace to another on plant floors without any assistance. In manufacturing sites, they play a crucial part in logistics optimization.

Advanced cameras, machine vision systems, and artificial intelligence are some of the technologies driving an assembly robot capabilities. These technologies make it possible for robots to carry out difficult tasks with outstanding accuracy and adaptability, ensuring their widespread use.

The Strategic Advantages of Robotic Assembly

Making the switch to robotic assembly has many strategic benefits for manufacturers, such as:

Boosting Productivity

Assembly robots can work nonstop, which greatly boosts production rates. They don’t need breaks like humans do, can work around the clock, and can be programmed to finish tasks faster. This faster speed means higher output, which helps manufacturers keep up with the needs of a growing market.

Quality Assurance

The ability to keep quality high is one of the best things about using assembly robots. Robots are programmed to carry out tasks with extreme accuracy, reducing human error and variability. Modern machine vision systems can find flaws in real time, ensuring that only goods that meet quality standards continue through the assembly process.

Cost-Efficiency

Even though robotic systems can cost a lot to buy at first, they often pay for themselves in the long run. Robotic assembly saves money on labor costs and waste by making things precise. Additionally, the improved productivity and efficiency can result in a faster return on investment (ROI), making it a smart financial choice for many manufacturers.

Innovations Fueling the Robotics Revolution

Robotic technology developments are driving a new wave of manufacturing automation:

AI and Machine Learning

The capabilities of assembly robots are changing a lot because of artificial intelligence. Robots can adapt to new tasks and develop their ability over time by using machine learning algorithms. For manufacturers to stay competitive in a market that is changing quickly, this adaptability is essential.

Integration with IoT

In contemporary manufacturing, the Internet of Things (IoT) plays a big part. By connecting robots to a network of sensors and devices, manufacturers can monitor performance in real time, gather data on production efficiency, and utilize this information to enhance processes. This amount of connectivity lets repairs be done before they break down, which cuts down on downtime.

Advanced Robotics Technologies

New technologies, like soft robotics, are making assembly robots more useful in more ways. Soft robots can handle delicate materials and goods, making them ideal for the food and consumer goods businesses. These new developments increase the flexibility of robotic systems, allowing them to perform more tasks.

Workforce Dynamics in the Age of Automation

This is how the workforce has changed because of the rise of robotic assembly:

The Shift in Workforce Roles

The jobs of human workers are changing as assembly robots take over monotonous tasks. Workers are spending more and more time overseeing, developing, and maintaining robotic systems instead of doing boring, manual tasks. Employees can now do more difficult and satisfying work thanks to this shift.

Training and Reskilling Initiatives

Companies must spend money on training and reskilling their workforce in order to adapt to these changes. To get the most out of automation, it’s important to teach workers the skills they need to use robots. Knowledge of how to design and fix robotic systems is part of this. So is the ability to look at data from Internet of Things (IoT) devices.

Enhancing Human-Robot Collaboration

Humans and robots can work together in the most productive manufacturing settings. Collaborative robots are designed to make this relationship possible, allowing for smooth human-sense and robotic precision integration. Establishing a collaborative mindset is crucial for the effectiveness of automation methods.

The Impact of Robotics on Supply Chain Efficiency

Supply chain efficiency is greatly improved by the integration of assembly robots. Manufacturers can shorten wait times and improve inventory control by automating crucial procedures. Robots make processes more efficient by ensuring that components are put together quickly and correctly, which cuts down on bottlenecks. This not only speeds up production but also makes it easier to meet the needs of the market. This lets manufacturers adapt quickly to changes in customer tastes and stay ahead of the competition in a fast-paced world.

Conclusion

The manufacturing landscape is changing as a result of the shift from human to robotic assembly, which has big benefits for efficiency, quality, and cost-effectiveness. Assembly robots will play a crucial part in driving the future of workplaces as they continue to advance. A new age of collaboration between humans and machines will be possible thanks to manufacturers’ embrace of this technological change, which will help them succeed in a market that is becoming more and more competitive.