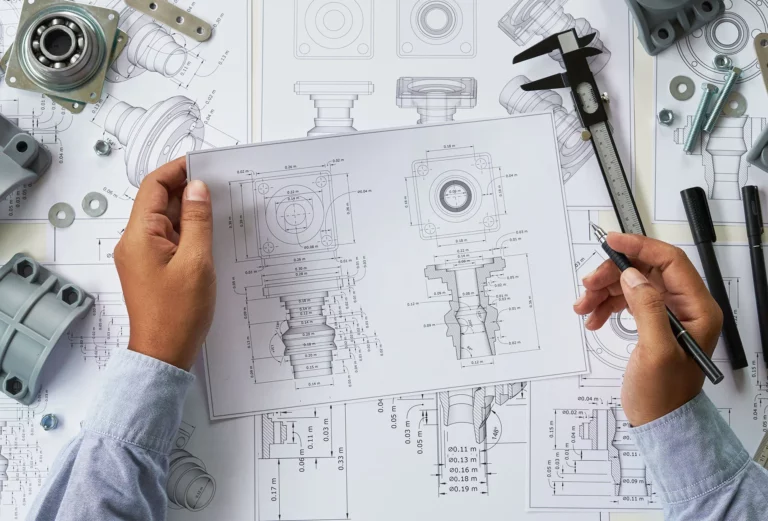

Mechanical design software, with its numerous tools and features, significantly accelerates the product development process, exemplifying innovation. Engineers can make accurate 3D models of goods, simulate their designs, and test them with the aid of Dassault Systèmes‘ engineering design software.

This helps them find design flaws and possible improvement areas quickly, which saves time and resources. It can also give exact cost figures, which help make sure the product can be made on time and on budget.

How Mechanical Design Software Can Transform Product Development?

Efficient Prototyping:

No longer are development methods that require a lot of work and use up a lot of time and resources necessary. With mechanical design software, engineers can make virtual versions that are more accurate and detailed than ever before.

Designers can test their designs’ functionality and performance in a virtual setting with advanced simulation tools. This lets them find any problems and make the necessary changes before going on to real prototyping. This not only speeds up the development process, but it also lowers the risks that come with expensive design changes.

Collaborative Design:

Successful product development depends on people being able to work together well. Mechanical design software makes it easy for team members to work together, even if they are in different places.

Engineers can collaborate on a single design at the same time using cloud-based platforms and real-time communication tools. They can share ideas, get feedback, and make changes quickly. This way of working together encourages new ideas and makes sure that every part of the product is carefully checked before it is made.

Iterative Design Process:

An open approach to design is necessary because product development is iterative. With the help of mechanical design software, designers can quickly and easily try out different designs.

Engineers can save time and effort by iteratively updating their designs with parametric models rather than starting from scratch. This iterative design process lets you try new things and get better quickly, which leads to better goods that meet the market’s changing needs.

Integrated Workflows:

From design and analysis to manufacturing and assembly, there are many steps that make up the product development process. The need for manual data sharing between various design tools is eliminated by the integrated methods offered by mechanical design software, which speeds up these processes.

By putting everything related to the design process on one platform, engineers can keep data safe, cut down on mistakes, and make sure that everything stays the same throughout the whole span of a product.

Simulation and Analysis:

From design and analysis to manufacturing and assembly, there are many steps that make up the product development process. The need for manual data sharing between various design tools is eliminated by the integrated methods offered by mechanical design software, which speeds up these processes.

By putting everything related to the design process on one platform, engineers can keep data safe, cut down on mistakes, and make sure that everything stays the same throughout the whole span of a product.

Customization and Automation:

From design and analysis to manufacturing and assembly, there are many steps that make up the product development process. The need for manual data sharing between various design tools is eliminated by the integrated methods offered by mechanical design software, which speeds up these processes.

By putting everything related to the design process on one platform, engineers can keep data safe, cut down on mistakes, and make sure that everything stays the same throughout the whole span of a product.

Enhanced Visualization and Communication:

Visualization is improved by mechanical design software, which lets designers make photorealistic models and videos that show off their designs in a vivid way. These visualizations are gexcellentfor communicating because they help people see the end product and give useful feedback early on in the development process.

Better representation makes it easier to communicate clearly and directly, which leads to unity and project success.

Conclusion

From design and analysis to manufacturing and assembly, there are many steps that make up the product development process. The need for manual data sharing between various design tools is eliminated by the integrated methods offered by mechanical design software, which speeds up these processes.

By putting everything related to the design process on one platform, engineers can keep data safe, cut down on mistakes, and make sure that everything stays the same throughout the whole span of a product.